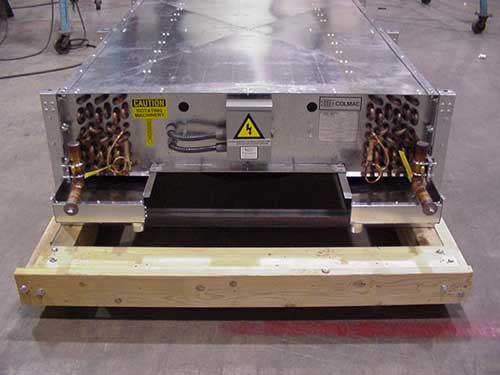

- These low velocity (LV) coolers are well suited for packed fruit handling and storage room installations because of limited headroom, low noise, and low air velocity requirements. Industrial coolers (low velocity) are designed for medium to large capacity low, medium, or high temperature rooms; fruit and/or vegetable processing or storage (facilities where cleanability is not critical), blast freezing tunnels, loading docks, and larger walk-in coolers. Standard units can be operated with wet or frosted fins, since coil face velocities are custom designed for each application; standard diameter aluminum propeller fans 20”, 24”, 26”, or 30”.

Features:

- Very Low Profile for Rooms with Minimum Headroom

- Gentle Airflow and Low Noise for Populated Work Areas

- Capacities up to 63 Tons (222 kW)

- Airflow up to 34,250 CFM (16,200 L/s)

- Horizontal Air Discharge

- 50 or 60 Hz Operation

- Ammonia, Freon, or Glycol Refrigerants

- Direct Expansion, Liquid Overfeed, or Gravity Flooded Circuiting

- Air, Water, Hot Gas, or Electric Defrost

- 20, or 24 inch Diameter Aluminum Propeller Fans

- TEAO Fan Motors with Internal Thermal Overload Protection

- Galvanized Steel Cabinet

- Hinged Drainpans

- Aluminum or Copper Tubes, with Aluminum Fins

- All Units Shipped Upright with Easy-to-Remove Shipping Legs

Options:

- All Aluminum, or All Stainless Steel Cabinet

- Dielectric Flange Union Connections for Ammonia

- Insulated Drainpan

- UL Listed Industrial Control Panels

Applications:

- Very Low Profile for Rooms with Minimum Headroom.

- Gentle Airflow and Low Noise for Populated Work Areas.

- Medium to Large Capacity for Low, Medium, or High Temperatures.

- Fruit and/or Vegetable Processing Rooms where Cleanability is NOT Critical.

- Blast Freezing Tunnels.

- Loading Docks or Areas.